|

"Better than a New Boat" is what some of our customers say after they have updated looks and function with a composite fiberglass and aluminum Custom Hardtop from Atlantic Towers. If your existing canvas top is looking a little tatty, before you commit for an expensive new bimini check out our full range of Custom Hardtops for boats in the 20 foot to 60 foot + size range.

Atlantic's family of custom ATL self trimming aluminum extrusions allows for Custom Hardtops of fiberglass and aluminum to be constructed with out the expense of a mold or time consuming edge finishing. (click here for full technical information) Typically 1/3 weight and 1/2 the cost of solid glass aftermarket hardtops, here are some of the reasons to consider an Atlantic Towers Custom Hardtops:

- LIGHT WEIGHT: A typical 70-80 square foot top weighs less than 150 pounds including supports and mounting hardware.

- STRONG: One piece all welded construction, means no bolted connection between heavy fiberglass lid and legs.

- FULLY ENGINEERED structure means no on-site welding and fitting. Atlantic Towers hardtops arrive ready to install.

- ENCLOSURE fits easily in optional track system, with hardtop overhang to protect from rain and spray (enclosure by others).

- LONGER LIFE from your enclosure. Fitting enclosures to a stable hardtop instead of a bimini reduces stress on zippers and fittings.

- REINFORCED to accept mounting of antennas, radar, search lights, and other equipment

- CONCEALED WIRING: Exclusive ATL self trimming mounts and hollow frame allow concealment of cables and equipment mounting bolts.

- CUSTOM DESIGN using our library of 1000s of production boat specs, allows customers to choose from a number of design possibilities or develop one of their own with the assistance of our design engineers.

|

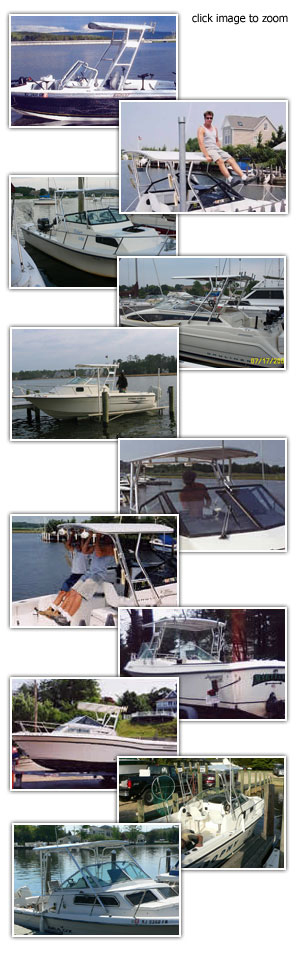

Custom Fishing Hardtop

|

|

If you have been looking for a solid, watertight enclosure that looks great

and is priced right, you've found it. Owners of smaller walk-around style

boats have found Atlantic's popular Custom Fishing HardTop to be the ideal

solution. A full 4 Rod Rocket Launcher is standard, along with mounts for

Halogen Spreader Cockpit Floodlights, a variety of antennas and Radar.

Each Tower is also as stylish as it is durable. To ensure design continuity,

each Custom Fishing HardTop is custom fabricated to match the existing lines

of your boat's windshield.

Atlantic's Hardtops are shipped complete with all the components and guidelines

needed for easy "bolt-on" installation. No welding is required'

eliminating the possibility of damaging your boat's finish. The best part

is, there is no need to leave your boat at some strange facility for days

or even weeks, while your

pipe work is being completed.

Standard Features

One piece all-welded top frame of Atlantic's proprietary ATL6 aluminum extrusion

and supporting legs of schedule 40 aluminum measuring nearly 2" O.D.

finished in 320 spiral texture and bright dip anodized. High quality hand

laid fiberglass top . 360 degree overhanging edge for weather protection,

with provision for canvas track installation . Two side mount antenna plates

and two halogen light mounts aft . Overhead hand rail running port to starboard

just aft of helm seat -Rectangular carlins (roof beams) for added strength

and to allow installation of reel hangers, rod racks and other equipment

. Custom aluminum fittings for attachment of supporting legs to boat . Stainless

steel hardware . Aluminum backup plates.

Atlantic's Custom Fishing Hardtop is specifically designed for retrofitting

to walk around and express style boats. With it's unique cantilevered design,

the Custom Fishing Hardtop requires no forward supports in it's normal configuration.

Nothing to obstruct your field of view from the helm, nothing to interfere

with front or side opening windshields, only clean lines and nothing to

interfere with an enclosure. Strong enough to support hundreds of pounds

of gear, and shrug off the beating a boat takes running offshore, yet very

light weight overall. In fact a Custom Fishing Hardtop weighs less than

100 pounds for most applications.

Each Custom Fishing Hardtop is made from high strength corrosion resistant aluminum alloys. The aluminum is spiral finished with a fine 320 abrasive, before it is given a chemical cleaning process called "bright dip" which gives it the appearance of brushed chrome, or brushed stainless. After bright dip, it is clear anodized, which is the build up of a hard clear oxide finish for maximin salt water protection. The perimeter hardtop frame is shaped using our proprietary ATL-6 aluminum extrusion. This extrusion provides a self-trimming recess for the hand laid fiberglass top surface, allowing it to be securely fitted to the all welded structural frame with no exposed fasteners. |

Using our proprietary database, each Atlantic Towers Custom Fishing Hardtop is custom designed and fabricated to order for your individual boat. The leading edge of the Custom Fishing Hardtop is shaped to conform to the shape of the windshield on your boat, for a factory installed look, and easy fit of a wrinkle free enclosure. The arch style legs are stylish, strong, and make for easy installation. The pipe used to fabricate the legs is 1 1/2" schedule 40 marine grade aluminum pipe, which measures 1.90" on the outside with a very heavy wall thickness.

By mounting on the cabin sides, Atlantic Towers unique mounting fittings help to isolate vibration from the gel coated fiberglass surface. This mounting position keeps the fittings high and out of the way of a person going to the bow on the side decks (they extend outward less than a typical antenna mount). It is also extremely strong, even though the fiberglass is not very thick in this area as the primary loads are in the fore and aft direction, the very direction in which the fiberglass cabin side is strongest. The mounts consist of a male pin in the arch, and a female fitting which is bolted to the boat with a supplied matching back up plate. Click Here for more mounting details. By mounting on the cabin sides, Atlantic Towers unique mounting fittings help to isolate vibration from the gel coated fiberglass surface. This mounting position keeps the fittings high and out of the way of a person going to the bow on the side decks (they extend outward less than a typical antenna mount). It is also extremely strong, even though the fiberglass is not very thick in this area as the primary loads are in the fore and aft direction, the very direction in which the fiberglass cabin side is strongest. The mounts consist of a male pin in the arch, and a female fitting which is bolted to the boat with a supplied matching back up plate. Click Here for more mounting details.

Base Price: $4999*

* Full width or expanded area top (most walk-around style boats with recessed side decks are at standard pricing, tops for traditional express style boats, larger runabouts, and extra wide walk-arounds require a top of more than 30 square feet at additional cost) $600.00

Traditional Leg Option Add $800 |

Custom

Hardtop

|

|

|

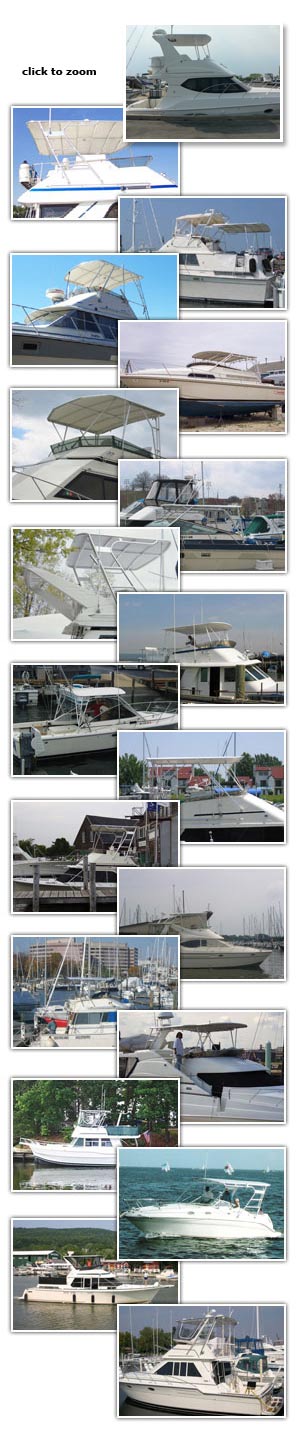

Full Custom Hardtop for Flybridge and Express Style Boats

Atlantic Towers ATL 6 self trimming aluminum extrusion combined with quality hand laid fiberglass allow the construction of Custom Hardtops that combine, strength, durability and attractive “factory like” design in a structure that is light in weight and available at reasonable cost (Custom Hardtop prices start in the high $3000s)

Each Atlantic Towers Custom Hardtop frame is made from high strength corrosion resistant aluminum alloys. The aluminum is brushed or spiral finished with a fine 320 abrasive, before it is given a chemical cleaning process called "bright dip" which gives the aluminum the appearance of brushed chrome, or brushed stainless. After bright dip, it is clear anodized, which is the build up of a hard clear oxide finish to maximize salt water protection. The perimeter hardtop frame is shaped using our proprietary ATL-6 aluminum extrusion (click here for details) . This extrusion provides a self-trimming recess for the hand laid fiberglass top surface, allowing it to be securely fitted to the all welded structural frame with no exposed fasteners. Using our proprietary database, and if necessary combined with measurements, drawings and photographs of your boat or a sister ship, each Atlantic Towers Custom Hardtop is designed and fabricated strictly to order for your individual boat. The leading edge of the Custom Hardtop is shaped to conform to the shape of the windshield on your boat, for a factory installed look, and easy fit of a wrinkle free enclosure. ATL 4 proprietary extrusions provide for concealed wiring and hidden accessory mounting bolts (click here for details)

Supporting leg structure in great part defines the style and esthetics of your hardtop, in addition to providing the structural support for a solid hardtop installation. Atlantic Towers, ATL 6 construction keeps hardtop weight to a minimum. As a result, supporting structure can be more esthetically pleasing. Heavy bridge type structures necessary to hold a 600 to 1000 pound cored fi berglass hardtop can be eliminated. In most cases, no special reinforcement to the boats fiberglass mounting surfaces will be required. Yet our installations are strong, and have routinely stood up to hurricane force winds well in excess of 100 mph.

Light weight means supporting legs can be shaped to an esthetically pleasing configuration. Most supporting structures fall into one of two categories, Arch Style, or Traditional Style. Although anything is possible and we can design configurations to attach to existing radar arches, funnels and other structures.

Arch style legs are stylish, strong, and make for easy installation. They add a contemporary look to older boats and typically do not interfere with bridge access, existing hand and guard rails, accessories etc. On flybridge boats, Arch Style legs eliminate the possible need to remove or cut headliners to install backing plates. They also provide the maximum flexibility in positioning of the hardtop when installed. The pipe used to fabricate the supporting legs is typically 1 1/2" schedule 40 marine grade aluminum pipe, which measures 1.90" on the outside with a very heavy wall thickness. Hardtops designed with Arch Style legs typically have 4 primary legs and mounting points, and may have two secondary sway braces, for a total of 6 attachment points.

Traditional Style Legs typically combine a three element rear supporting leg, with a pair of forward primary supporting legs and two, four or more secondary braces. Atlantic Towers Custom Hardtops with Traditional Style legs, have a least 6 attachment points and frequently 8 or more. In the 1980s many new flybridge fishing boats were fitted with aftermarket fabric topped “Half Towers” which was simply a permanent top, without the upper steering station. These structures all had Traditional Style supporting legs. As a result this style supporting leg is still popular today with the owners of earlier sport fishermen, convertibles and other traditionally styled boats.

Many other configurations are possible as well, providing for attaching Atlantic Towers Custom Hardtops to existing arches, supporting cockpit sunshades, aft deck hardtops on motor yachts and aft cabin boats. (see tuna towers and other specialty structures) |

|

|

Contact our knowledgeable sales staff 6 days a week to discuss the Custom Hardtop possibilities for your boat, and to receive a fast and accurate quotation. (Telephone 800-831-8889; Fax 609-361-8500; email: sgolden@atlantictowers.com ) |

|

Shipping

|

|

All Atlantic Towers Custom Hardtops are completely engineered products. They are ready for installation without any field welding or additional fabrication when they leave our plant. As a result, they can be packed and shipped anywhere in the world.

Or for considerable freight savings, Supporting legs and structure may be designed to demount using one of several Atlantic Towers custom hardware fittings. Larger tops may then be shipped "flat" as in the photos below.

|

|